SPX FLOW - APV Mixer

Mixing

and Blending

and Blending

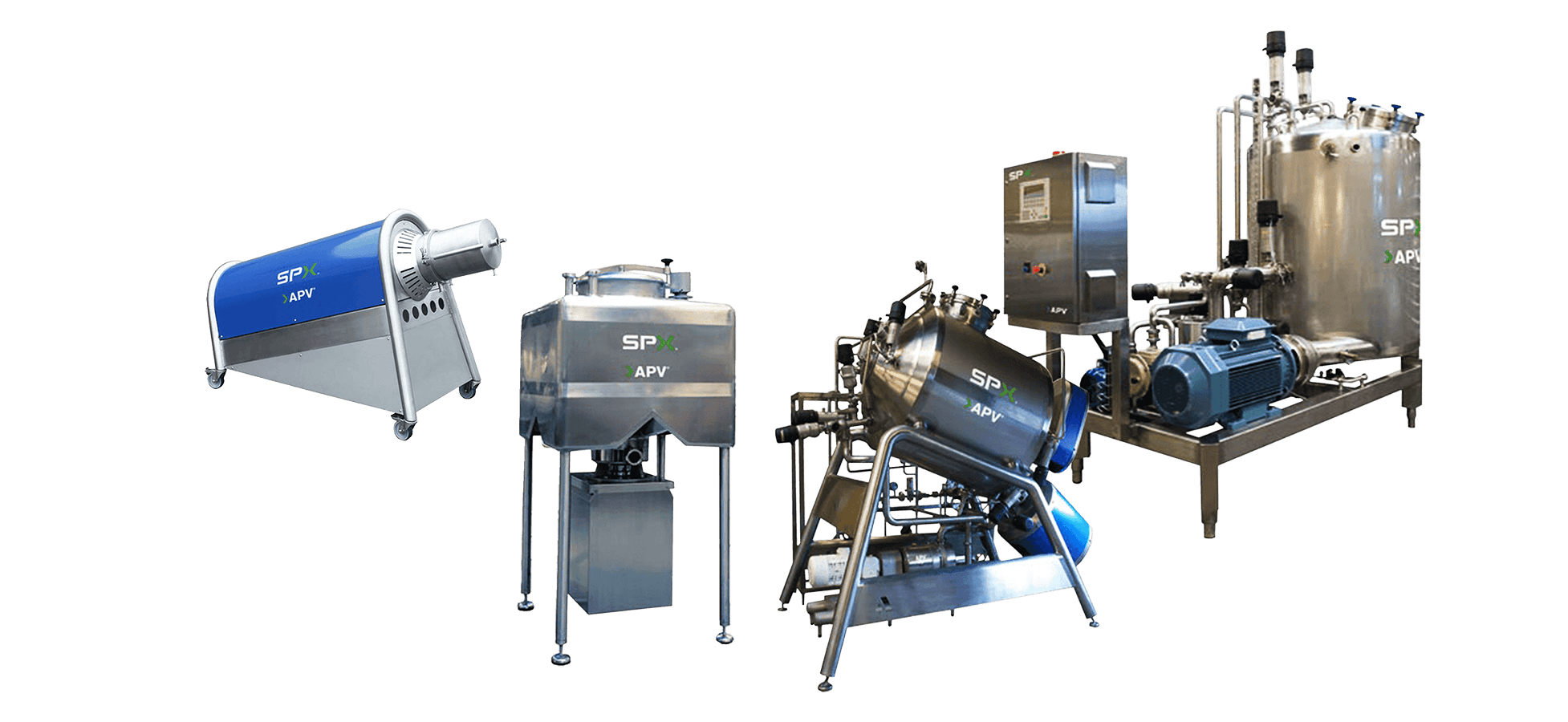

Mixing and blending is one of SPX FLOW's core technologies, designed to help customers develop new products and processes, improve product quality and shelf-life and provide better consistency. An extensive mixer portfolio offers the flexibility to handle all types of products, quickly and efficiently. SPX FLOW's specialized mixing and blending systems fulfil customer requirements in industries as diverse as food & beverage, brewery, dairy and personal care.

With paramount importance to food safety, all APV products are designed to the highest hygiene standards for easy cleaning. Here are the product lines under SPX FLOW's mixer brand:

Flex-Mix Mixer Line

Flex-Mix Instant Mixer

Designed for batch mixing, inline mixing over one or more hydration tanks or continuous mixing in closed systems with vacuum powder transport. Powder is sucked into a circulating liquid by vacuum. The dispersed powder is homogenized by passing it through the mixer head located next to the tank. Feature highlights include:

- Unique high shear mixing enables a high powder intake

- Air is efficiently removed during mixing prolonging running time and ensuring consistent quality

- Closed, continuous production, resulting in higher throughput and reduce dust issues

- Large number of formulation - flexible

Flex-Mix Liquiverter

Manual unit designed for batch mixing, inline mixing over one or more hydration tanks, or continuous mixing, with optional integration in fully automated production. Available as standard unit or with a high-shear mixing option. The mixing principle in the liquiverter is based on vortex-driven blending. The liquid collapses around the powder and is forced towards the mixer head at the base. Feature highlights include:

- Simple yet versatile

- Flexibility at low CAPEX

- Large dissolution capacity due to free vortex and square shape

- Fully drainable for improved hygiene and minimum waste

- Direct drive reduces spare parts wear

- Flushed double mechanical seal available

- Ease of maintenance

Flex-Mix Power

High shear, stand-alone, in-line mixer, suitable for processing liquid/liquid and liquid/gas dispersions. Optional aseptic mixing available. Aseptic gas injection is used to make an aerated product. Liquid is dosed into a rotor/stator pin mixer for high shear emulsification. Feature highlights include:

- Aseptic aeration

- Emulsification

- Continuous mixing

- PLC standard in all aseptic systems

- Operator-friendly, smooth and trouble-free operation

- Pre-assembled and factory-tested

Flex-Mix Processor

Sanitary batch process with processing and cooling in a time frame similar to that of a continuous process. Special mixing agitator designed for gentle processing and protection of product integrity. Optional high shear mixing unit for emulsification. High viscosity products are pushed towards the mixer at the base by the agitator in the middle. A circulation pump can pass the product through the mixing head several times. Feature highlights include:

- Gentle agitation, internal circulation

- High shear mixing for emulsification

- Particles handling

- Heating via jacket or direct steam injection

- Closed system with vacuum/flash options

- Quick batch preparation (flip-flop)

TPM Batch Powder Mixer

For dispersion of highly soluble powders. Powder is added to the mixer via a butterfly valve. The valve controls the flow of powder and prevents air entering the mixer. Feature highlights include:

- Easy to maintain - the shaft seals are changed easily

- Reliable design due to the sturdy construction

- Hygienic, CIP-friendly design

- Reduced maintenance costs

DarMix+ In-Line Mixer

Compact and highly efficient in-line mixer. Mixing intensity (rpm) controlled by a frequency converter. Feature highlights include:

- Applicable for high- and low-viscosity products

- Homogenization effect

- No product contacting bearings

- Compact design

- Simultaneous cleaning with pipeline

TPX Static In-Line Mixer

Feature highlights include:

- 3A certified

- Low-cost mixing alternative - no tank is required

- Reliable mixing directly in the pipes

- Easy to maintain

- Fast and easy CIP-cleaning

APV Cavitator

SPX FLOW offers an innovative next generation technology called the APV Cavitator. This patented technology offers breakthrough benefits for the heating of liquids without scaled buildup and/or the mixing of liquids with other liquids, gasses or solids at the microscopic level to improve product quality and functional performance.

APEQ Process is an official distributor of SPX FLOW, APV in Malaysia.

Need a price quotation?

Enquire now >

About SPX FLOW and APV

Based in Charlotte, North Carolina, SPX FLOW innovates with customers to help feed and enhance the world by designing, delivering and servicing high value solutions at the heart of growing and sustaining our diverse communities.

APV, an SPX FLOW Brand, provides a unique range of highly functional solutions, systems and products that address key business drivers. SPX FLOW bases its APV solutions on advanced technology products including pumps, valves, homogenizers, mixers and heat exchangers, as well as production efficiency experience, development expertise, maintenance management and regulatory compliance.

Catalogue/ Brochure/ Technical Specification

APV Mixing and Blending Technology Brochure

APV Flex-Mix Line Brochure

APV Flex-Mix Instant Mixer Brochure

APV Flex-Mix Liquiverter Brochure

APV TPM Batch Powder Mixer Brochure

APV DarMix+ In-Line Mixer Brochure

APV TPX Static In-Line Mixer Brochure

APV Cavitator Brochure

APV Flex-Mix Liquiverter User Manual